Tel.: 8 (800) 333-41-10, 8 (495) 966-18-90

www.mobiprof.ru, info@mobiprof.ru

|

115054, Moscow, st. Dubininskaya, d. 69, building thirty Tel.: 8 (800) 333-41-10, 8 (495) 966-18-90 www.mobiprof.ru, info@mobiprof.ru |

|

||||||||||||

|

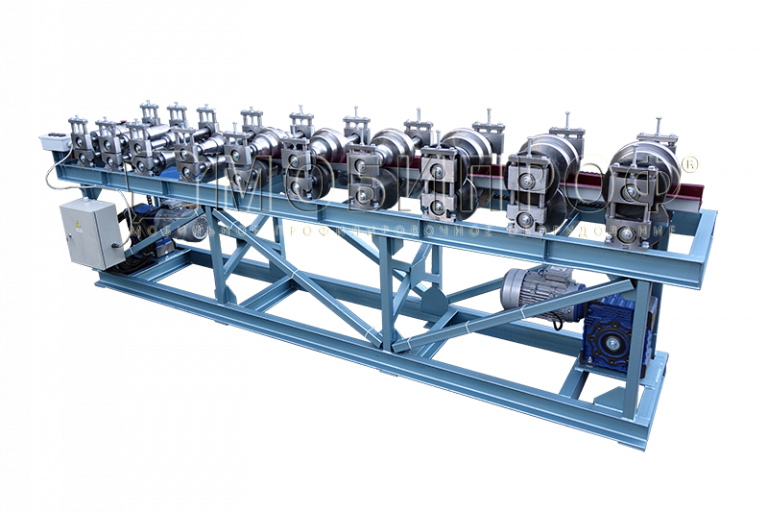

Gutter roll forming machine is intended to produce of a gutter from thin-sheet galvanized steel 0,4-0,6 mm of thickness with plastisol or pural coatings. Gutter is one of the elements of the rain ware system responsible for draining rainwater and meltwater from the roofs of buildings. Gutter forming machine can operate in semi-automatic and automatic mode. In semi-automatic mode operator should press “Start” button and provide feeding of specific cut length blanks into the machine. In the automatic mode, the line shall comprise a band decoiler for feeding metal into the machine, a device for cutting the profiles into specific cut lengths and numeric control system. Our numeric control with touchpad has a user-friendly interface with various controlled parameters. The system is also equipped with alarm and error indicators and support information as well as maintenance service information. To get a quotation of the equipment you should write us by e-mail: info@mobiprof.ru or call us. A custom build roll forming machine based on the customer’s drawings can be manufactured. |

||||||||||||

Benefits

|

||||||||||||

Specifications

|

||||||||||||

Cost and availability

|

||||||||||||

Options

|