Tel.: 8 (800) 333-41-10, 8 (495) 966-18-90

www.mobiprof.ru, info@mobiprof.ru

|

115054, Moscow, st. Dubininskaya, d. 69, building thirty Tel.: 8 (800) 333-41-10, 8 (495) 966-18-90 www.mobiprof.ru, info@mobiprof.ru |

|

||||||||||||

|

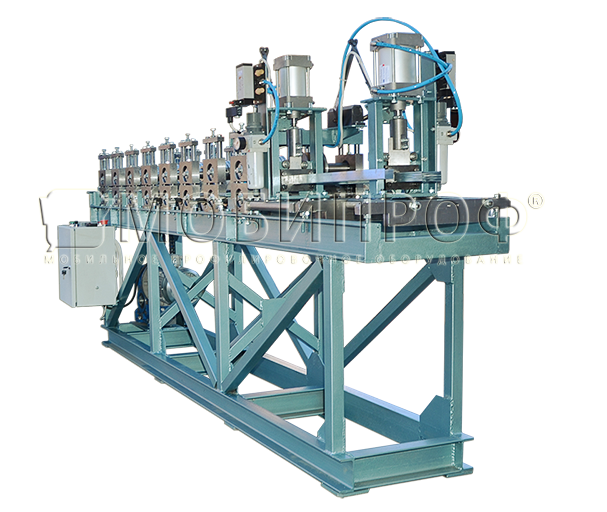

The GK series machine is intended for profiling of CD and UD profile from thin-sheet galvanized steel 0,4-0,7 mm of thickness. Either strips of some width, or flats of the same width and desired length are used as blanks. It manufacture standard shapes CD 60х27 and UD 28х27, the blank width is 123 mm and 81 mm. Plasterboard profiles roll forming line includes a roll forming module, a pneumatic flying shear for transversal cutting after rolling, and numeric control system (NC). Optional operator touchpad for NC makes the process of parameter entry and monitoring much easier, and allows entering into the machine memory up to 10 different production programs (length and quantity). In addition, the machine can be equipped with a notching unit 60х27, and flying hole punching device 28х27.

When rolling shapes from flats of the required width and length the guillotine and NC are unnecessary, which reduces the gypsum plasterboard shaping equipment cost, the capacity being reduced accordingly. One person is necessary when operating with a roll. The operator engages the flat, sets the operation mode for the control system (length, quantity of items and speed). The “flying cut” device allows increasing the automatic shape production line capacity by 25-30% as compared with stationary cut and by 50% as compared with the machine without the control system, thus decreasing the cost of produced items and making the shape for gypsum plasterboard a very promising business. The excellence of final products is ensured with automatic control system and monitoring of master schedule exactitude.

We can also manufacture custom-built machines for plasterboard profiles. Plasterboard profile roll forming line versions:

|

||||||||||||

Benefits

|

||||||||||||

Specifications

|

||||||||||||

Cost and availability

|