Tel.: 8 (800) 333-41-10, 8 (495) 966-18-90

www.mobiprof.ru, info@mobiprof.ru

|

115054, Moscow, st. Dubininskaya, d. 69, building thirty Tel.: 8 (800) 333-41-10, 8 (495) 966-18-90 www.mobiprof.ru, info@mobiprof.ru |

|

||||||||||||

|

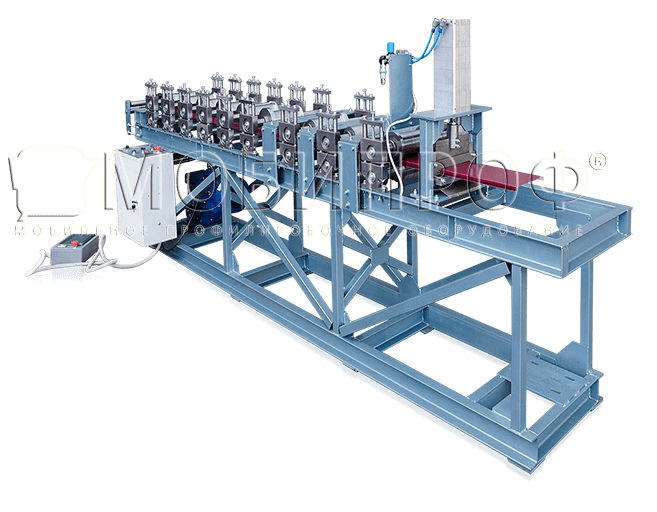

SO series roll forming machines are designed to produce metal siding - Linear panel /Ship Deck It is roll formed from light gauge galvanized steel with polymer coating: polyester, plastisol 0.4 to 0.7 mm thickness. Workpiece must be a certain width and pre-catted of required length or a rolled up strip. The optimized configuration of shaping rollers ensures smooth bending of the shapes and consistent dimensions over the whole length of the product.

The machine for metal siding profile is equipped with a preliminary punching module for mounting holes, feeding and calibration mill stands, heavy-duty bearing housings. It is designed to produce only one shape type. The most popular shape types: - Linear panel /Ship Deck/Bar.

The siding production machines are custom-built on pre-agreed profile drawing. The lead time is 4 to 8 weeks. To get a quotation of the equipment you should write us by e-mail: info@mobiprof.ru or call us.

A custom build roll forming machine based on the customer’s drawings can be manufactured. * On the photo, the machine shown with optional equipment. |

||||||||||||

Benefits

|

||||||||||||

Specifications

|

||||||||||||

Cost and availability

|