Tel.: 8 (800) 333-41-10, 8 (495) 966-18-90

www.mobiprof.ru, info@mobiprof.ru

|

115054, Moscow, st. Dubininskaya, d. 69, building thirty Tel.: 8 (800) 333-41-10, 8 (495) 966-18-90 www.mobiprof.ru, info@mobiprof.ru |

|

||||||||||||||

|

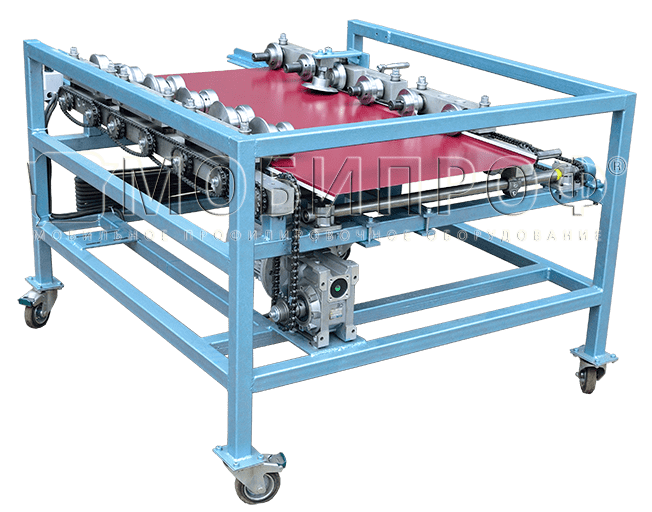

PK.R series roll forming machines are equiped with stepless width adjustment and the machines are intended for profiling “Window drip cap” profile in a single pass and availability of the system of automatic adjustment to metal thickness which makes operation much simpler and increases productivity.

The user-friendly machine design allows quick switching over between the strip widths. It is performed by rotating the handle, during its rotation one support with rollers moves, the other does not move.

Copper, galvanized steel, steel with polymer coating zinc-titanium, hot- and cold-rolled steel up to 0.8 mm thick can be used as a material to be rolled.

Bearing supports made of aluminium decrease the machine weight significantly. The movable guides allow you to change the size of the outer elements of the profile.

To get a quotation of the equipment you should write us by e-mail: info@mobiprof.ru or call us. A custom build roll forming machine based on the customer’s drawings can be manufactured. |

||||||||||||||

Benefits

|

||||||||||||||

Specifications

|

||||||||||||||

Cost and availability

|

||||||||||||||

Options

|