Tel.: 8 (800) 333-41-10, 8 (495) 966-18-90

www.mobiprof.ru, info@mobiprof.ru

|

115054, Moscow, st. Dubininskaya, d. 69, building thirty Tel.: 8 (800) 333-41-10, 8 (495) 966-18-90 www.mobiprof.ru, info@mobiprof.ru |

|

||||||||||||||

|

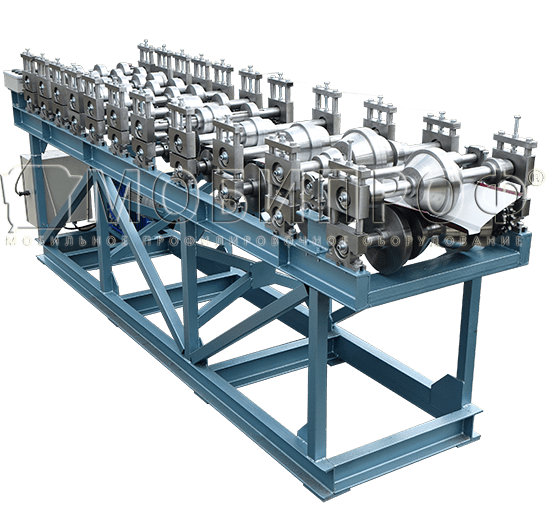

The machines are designed for producing “ridge cap” or “neck cap” profiles of 0.4 to 0.6 mm galvanized steel with different types of polymer coating.

The machines operate both with specific cut lengths, and with metal coiled into a roll (strip) and is an efficient solution for manufacturing a large number of shapes of different standard sizes, significantly improving production activity of the enterprise producing roofing products. The optimized configuration of shaping rollers ensures smooth bending of the profile and consistent dimensions over the whole length of the product.

The equipment is mobile, reliable and simple in operation and maintenance. Due to its small overall dimensions and weight, it can be used not only in a shop, but also on a construction site.

Application fields:

To get a quotation of the equipment you should write us by e-mail: info@mobiprof.ru or call us. A custom build roll forming machine based on the customer’s drawings can be manufactured. |

||||||||||||||

Benefits

|

||||||||||||||

Specifications

|

||||||||||||||

Cost and availability

|

||||||||||||||

Options

|